-Productos-

Contacto

- Linyi GiantLin Machinery

- Email:

- admin@giantlinmachinery.com

- WhatApp/Teléfono:

- 0086-15269722300

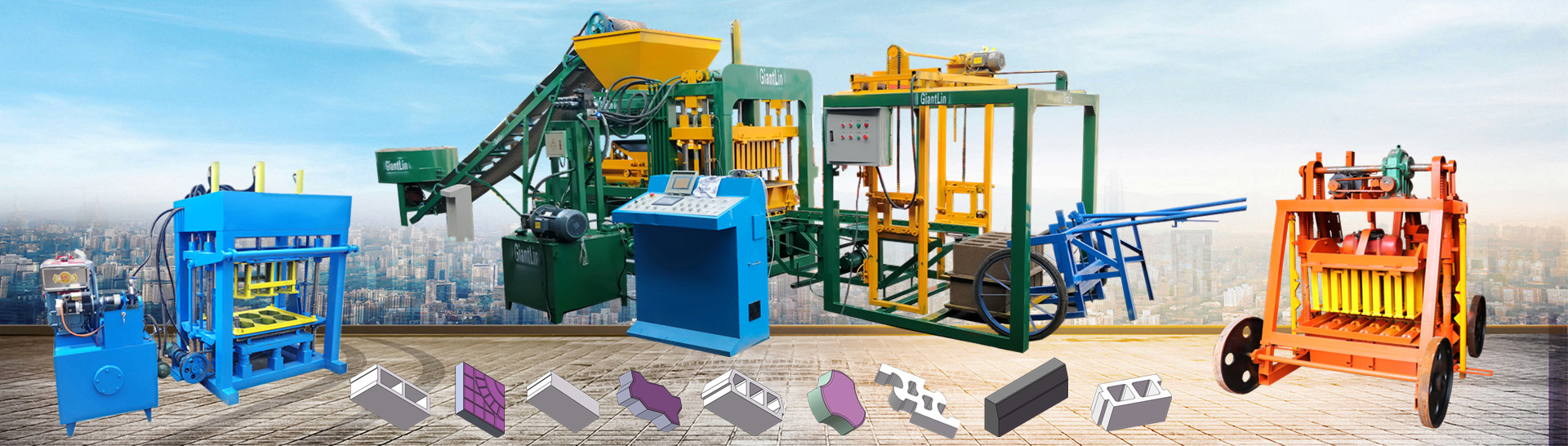

Máquina de bloques automática

Su ubicación actual:First > Máquina de bloques automática

QT10-15 automatic cement pavement brick machine

Descripton:

QT10-15 automatic cement pavement brick machine

Features:

1. QT10-15 is a fully automatic PLC (3 control cores)with hydraulic system brick machine. This machine no need worker control, easy operation.

2. QT10-15 could produce different size and shape hollow block, solid block, interlocking brick, paving brick, color face paver and curbstones.

3. QT10-15 is classical big machine, it could work durable and stably.

4. QT10-15 has bigger vibration force and better hydraulic system, it could produce faster and better quality blocks.

5. Big production capacity: Max. production capacity: 307CBM standard hollow blocks per 8 hours.

More Photos:

Specification:

Bricks design samples produced by machine:

Production Capacity

| Block type | Size and Production Capacity | Block photo |

| Hollow block | 400-200-200mm 10 pcs/mold 19200 pcs/8 hours | A1 |

| Holland block | 200-100-60mm 28 pcs/mold 53760 pcs/8 hours | D1 |

| Zig Zag brick | 225-112.5-60mm 24 pcs/mold 46080 pcs/8 hours | D3 |

| I shape paver | 200-160-60mm 18 pcs /mold 34560 pcs/8 hours | D2 |

QT10-15 automatic cement pavement brick machine technical information:

| QT10-15 Host machine total power | 44.5kw |

| Molding cycle | 10-15s |

| Vibration frequency | 4600-5200hz |

| Vibration force | 100kn |

| Rated pressure | 21mpa |

| Host brick machine size | 7500*2500*3020mm |

| Net Weight | 9800KG |

| Pallet size | 1100-870MM |

| Workers | 2-4 workers for block machine |

| Factory area size | 2000sqm |

| Main parts | PLC: Vigor from Taiwan; Inductor/Switch: CHNT&Schnelder |